Below is a list of materials that we commonly work with

Metals

1008 Steel

This low-carbon steel is often used for its good formability and weldability. In seal applications, it might be chosen for its affordability and suitability for certain structural components or housings.

5052-H32 Aluminum

This aluminum alloy is known for its excellent corrosion resistance and formability. It’s lightweight, making it suitable for components where weight reduction is important without sacrificing mechanical properties.

6061-T6 Aluminum

Another aluminum alloy, 6061-T6 is known for its strength, good corrosion resistance, and weldability. It’s often chosen when higher strength and hardness are required compared to 5052 aluminum.

304 Stainless Steel

This stainless steel grade is widely used due to its excellent corrosion resistance, good formability, and durability. It’s suitable for seals exposed to moisture, chemicals, or other corrosive environments.

316 Stainless Steel

Known for its superior corrosion resistance compared to 304 stainless steel, 316 is often used in seals where exposure to harsh chemicals or saline environments is expected. It offers excellent performance in marine and industrial settings.

Hastelloy C-276

This is a super-alloy known for its exceptional corrosion resistance to a wide range of chemicals, including acids, chlorides, and other harsh environments. It’s chosen for seals in extremely corrosive applications where standard stainless steels may not suffice.

D2 Tool Steel

D2 tool steel is a high-carbon, high-chromium, air-hardening tool steel known for its excellent wear resistance and toughness. This is typically the material T3 uses for our tooling.

PTFE

Virgin

Pure PTFE without any fillers, offering good chemical resistance and low friction.

Good for chemicals, water, steam, gases, oils

Graphite Filled

Adds lubricity, thermal conductivity, and electrical conductivity. Used in applications requiring enhanced wear resistance and low friction.

Good for aggressive chemicals, moderate to high-pressure gases, oils.

Carbon Filled

Improves wear resistance and dimensional stability. Often used in dynamic sealing applications.

Good for hydraulic fluids, water, mild acids, hydrocarbons, gasoline, solvents.

Carbon / Graphite Filled

Combines properties of both carbon and graphite for improved wear resistance and conductivity.

Good for high-temp oils, aggressive chemicals, fuels, water.

Euro Graphite Filled

Graphite with enhanced properties specific to European standards or specifications.

Good for aggressive chemicals, high-pressure gases, hydraulic fluids, oils, solvents.

Ceramic Sphere / Euro Graphite Filled

Incorporates ceramic spheres for improved wear resistance and dimensional stability.

Good for aggressive chemicals, high-pressure gases, hydraulic fluids, oils, solvents.

Glass Filled

Enhances compressive strength, wear resistance, and dimensional stability. Used in applications where increased mechanical strength is needed.

Good for water, hydraulic fluids, oils, gasoline, refrigerants, mild acids.

Glass / Moly Filled

Combines glass with molybdenum disulfide for improved wear resistance and low friction.

Good for hydraulic fluids, oils, fuels, water, gases, moderate chemicals.

Glass / Cobalt Filled

Combines glass with cobalt for improved wear resistance and high-temperature stability.

Good for water, hydraulic fluids, oils, gasoline, refrigerants, mild acids and bases.

Carbon Fiber Filled

Increases strength, stiffness, and wear resistance. Suitable for high-performance applications.

Good for harsh chemicals, high-temperature oils, abrasive media, solvents, fuels.

Carbon Fiber / Titanium Ferrous Oxide (Modified)

Increases strength, stiffness, and wear resistance. Suitable for high-performance applications.

Good for harsh chemicals, high-temperature oils, abrasive media, solvents, fuels.

Polyimide Filled

Provides high temperature resistance and low outgassing properties, suitable for aerospace and electronic applications.

Good for aerospace fluids, high-temperature gases, oils, solvents, electronics cooling fluids.

Ekonol Filled

Provides high temperature stability and resistance to wear and chemicals.

Good for high-temperature oils, harsh chemicals, solvents, fuels, hydraulic fluids.

Mineral Filled

Typically used to modify mechanical properties such as hardness and wear resistance.

Good for water, hydraulic fluids, mild acids and bases, oils, solvents, refrigerants.

Plastics

Nylon

Known for its high strength, toughness, abrasion resistance, and good chemical resistance.

Nyloil

Known for its self-lubrication, wear-resistance, high strength, and stiffness. Machineability is very good, and is a commonly used material for seal installation tools.

UHMW (Ultra-High Molecular Weight Polyethylene)

Very high abrasion resistance, low coefficient of friction, good chemical resistance, and impact strength.

PVC (Polyvinyl Chloride)

Good chemical resistance, electrical insulation properties, and flame retardancy (with additives). Very good machineability and is also a commonly used material for seal installation tools.

PEEK (Polyether Ether Ketone)

High temperature resistance, excellent mechanical properties, chemical resistance, and dimensional stability.

TIVAR HOT (Modified Ultra-High Molecular Weight Polyethylene)

High abrasion resistance, impact strength, and temperature resistance up to 275°F (135°C).

ULTEM (Polyetherimide)

High strength, stiffness, heat resistance (up to 340°F or 171°C), and excellent electrical properties.

Gasket Materials

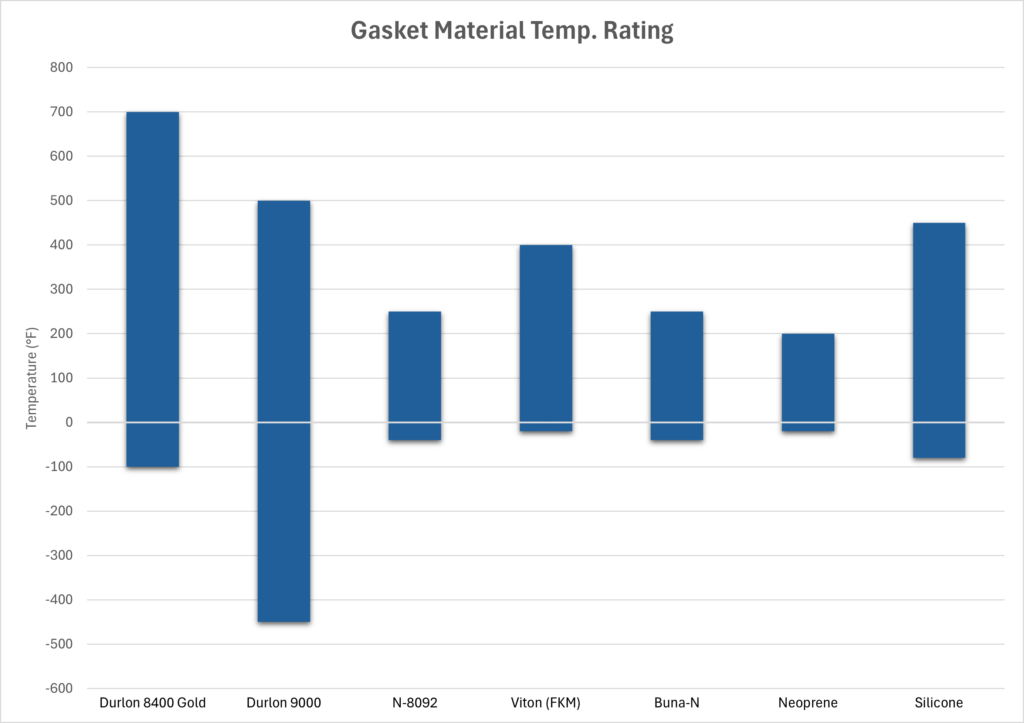

Durlon 8400 Gold

A high-performance compressed sheet gasket material that combines aramid and inorganic fibers with a high-quality rubber binder. It’s designed for use in a wide range of industrial applications, providing excellent seal-ability and chemical resistance. Also works well in applications involving water, oils and fuels.

Durlon 9000

A premium grade PTFE-based gasket material filled with glass microspheres. It offers exceptional chemical resistance and is suitable for a wide range of aggressive chemical applications, including those involving strong acids and caustics. Good for cryogenic applications.

N-8092

A cellulose fiber-based gasket material often used in automotive, marine, and industrial applications. It is designed for applications involving water, oil, and fuels, providing good sealing properties at a low cost.

Viton (FKM)

A high-performance fluoroelastomer known for its excellent resistance to high temperatures, chemicals, and oil. Viton is commonly used in automotive, aerospace, and industrial applications where high heat and aggressive chemicals are present.

Buna-N

Buna-Nitrile is a synthetic rubber material known for its excellent resistance to oils, fuels, and other petroleum-based products. Buna-N is widely used in automotive, aeronautical, and industrial applications where oil resistance is required.

Neoprene

A versatile synthetic rubber with good chemical stability and flexibility over a wide temperature range. Neoprene is used in a variety of applications, including automotive, industrial, and marine environments.

Silicone

A synthetic elastomer known for its excellent thermal stability, flexibility at low temperatures, and resistance to UV light, ozone, and weathering. Silicone is commonly used in food, medical, automotive, and industrial applications.